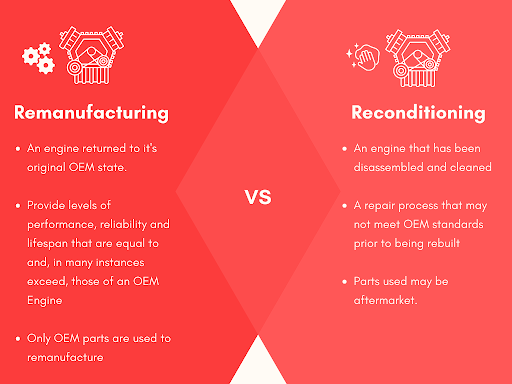

What is the difference between engine remanufacturing & engine reconditioning?

Reconditioned Engine

A reconditioned engine is an engine that has been disassembled, machined, and cleaned. Parts have been replaced with most likely non-genuine aftermarket components, and a repair process that may not meet Ford’s OEM (Original Equipment Manufacturer) standards before being rebuilt.

Remanufactured Engine

A remanufactured engine has been returned to Ford's original factory specification using all genuine Ford parts. As a result, remanufactured engines provide levels of performance, reliability, and durability equivalent to a new engine, as manufactured by Ford.

Note: A remanufactured engine is not the same as a reconditioned engine or a repaired engine.

Note: Image developed and approved for use by Original Engines.

A detailed process is followed by our engine suppliers, which includes inspection and checking of components to ensure Ford’s remanufactured specifications are met and all components meet hardness, dimensional, and clearance critical standards.

Furthermore, Ford’s remanufactured engines are required to meet their global requirements with known mandatory OEM replacement components that include the following key parts:

- Pistons and rings

- Big and small end bearings

- All gaskets and oil seals

- Timing chains and belts

- Rocker and valve assemblies

- Yielded fasteners throughout the engine

Additionally, important machining and assembly operations are imperative in achieving this high level of remanufactured product. Ford’s remanufactured engine suppliers are under a strict quality management system that ensures Ford’s customers are provided with a consistently high-standard, quality product, including a hand-built blueprint specification process to ensure reliability.